Numerous manufacturers have successfully adopted an ERP system to increase productivity and streamline corporate operations. However, integrating a Warehouse Management System with an ERP system can provide value for businesses with extensive inventories and warehouse facilities.

A Warehouse Management System (WMS): What Is It?

For a warehouse to manage inventory effectively, a Warehouse Management System (WMS) is essential. It includes tracking inventory products from start to finish, including picking, packing, shipping, put-away, and receipt. WMS systems optimise inventory flow and positioning within the warehouse by giving real-time insights. While ERP systems gather and handle data from several departments inside the company, including inventory management, they need a dedicated WMS’s comprehensive features.

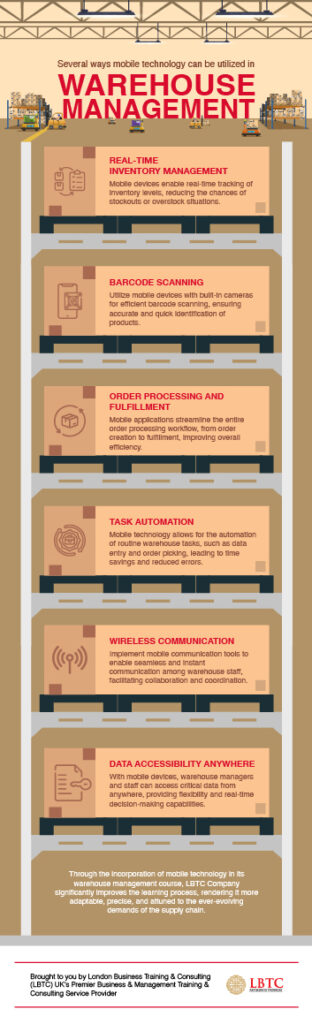

A WMS provides particular features that improve inventory control and warehouse operations:

- The capacity to precisely track and manage inventory in real-time, including locations, movements, and stock levels.

- Optimising cycle counting, stock adjustments, picking techniques, put-away, replenishment, and returns management in the warehouse.

- Give thorough insight into warehouse operations and performance measurements, offering information on order statuses, inventory levels, and operational effectiveness.

- Support for RFID and barcode technologies to enable precise and effective inventory management and speed up data collection procedures; smooth interaction with other business systems, such as ERP; and possibly e-commerce platforms to make data synchronisation and operations easier.

- The capacity to grow and adjust to new business demands, considering the need for various warehouse sites, higher inventory volumes, and changing industry standards.

Many small firms discover that their ERP system’s inventory management features adequately meet their inventory needs economically and efficiently. They might not need the extra specialised features that a dedicated WMS offers.

Only some warehouses need a WMS, mainly if its operations are simple and straightforward. WMS systems are usually made to handle more complicated warehouse operations, such as those with numerous sites, higher inventory volumes, sophisticated optimisation tools, and advanced picking tactics. Your ERP system should be sufficient for smaller warehouses with fewer inventory items and more straightforward procedures.

Warehouse Management System Advantages Over ERP

- A WMS integrated with an ERP system can have a significant impact.

- Improved insight into inventories, including current stock-level information.

- Using previous data, it enhanced demand forecasting by identifying top-selling items and the best possible warehouse locations.

- Just-in-time inventory procedures are implemented, allowing for quicker product movement.

- Efficient operations as a result of receiving and shipping procedures that are optimised based on resource availability.

- Improved picking effectiveness, decreased error rates, and shorter order fulfilment times.

- Better customer service by keeping proper stock levels and delivering orders on schedule.

- It improved data security by reducing the possibility of theft and errors and allowing personnel access to pertinent information.

- Increased efficiency in the warehouse by simplifying intricate processes and freeing up employees to work on more business-focused duties.

Here’s a rewritten and explained summary of the pointers:

Consider a Warehouse Management System (WMS) if you’re facing:

- Rising Labor Costs: A WMS helps you optimise tasks, automate processes, and consolidate roles, saving on labour expenses while boosting worker efficiency.

- Frequent Errors: Damaged goods, wrong shipments, and customer complaints signal inefficiencies. A WMS automates tasks and storage, minimising human error and improving accuracy.

- Limited Space: A WMS helps you optimise warehouse layout and automate processes, maximising space utilisation and saving time and money.

A WMS integrates with ERP systems for comprehensive inventory management. Evaluate your inventory and warehouse operations to determine if a WMS would be beneficial. If your warehouse operations are inefficient, error-prone, or space-constrained, a WMS can help you streamline processes, save costs, and improve inventory management. Elevate your efficiency, minimise errors, and maximise space utilisation by considering a WMS – the key to a more streamlined and cost-effective warehouse course.

Leave a Reply